What Is a Hearing Conservation Program?

A hearing conservation program is not just a box to check for safety compliance-it’s a life-saving system designed to stop noise-induced hearing loss before it happens. In workplaces where machinery, tools, or equipment create loud noise, employees are at risk. The U.S. Occupational Safety and Health Administration (OSHA) requires these programs when workers are exposed to noise levels of 85 decibels (dBA) averaged over an 8-hour workday. That’s the sound of a lawnmower, a busy city street, or a power saw running for hours. Left unchecked, this kind of exposure leads to permanent, untreatable hearing damage.

According to the National Institute for Occupational Safety and Health (NIOSH), about 22 million American workers are exposed to dangerous noise levels every year. And it’s not just factory workers. Construction crews, airport staff, farmers, musicians, and even warehouse employees in busy distribution centers are at risk. The good news? When done right, hearing conservation programs can reduce hearing loss by 30 to 50%. The bad news? Most programs fail-not because they’re too expensive, but because they’re poorly executed.

OSHA’s Five Required Components

OSHA doesn’t leave room for guesswork. A legal hearing conservation program must include five core elements, all of which must be documented and followed consistently.

- Noise monitoring: Employers must measure noise levels using calibrated sound level meters or noise dosimeters. This isn’t a one-time task. If you add a new machine, change a layout, or upgrade equipment, you must retest. Monitoring identifies which areas and jobs require hearing protection.

- Audiometric testing: Every employee exposed to 85 dBA or higher must get a baseline hearing test within six months of starting the job. After that, annual tests are mandatory. These tests check hearing sensitivity at key frequencies-500, 1000, 2000, 3000, and 4000 Hz-and must be done in quiet rooms that meet OSHA’s background noise standards.

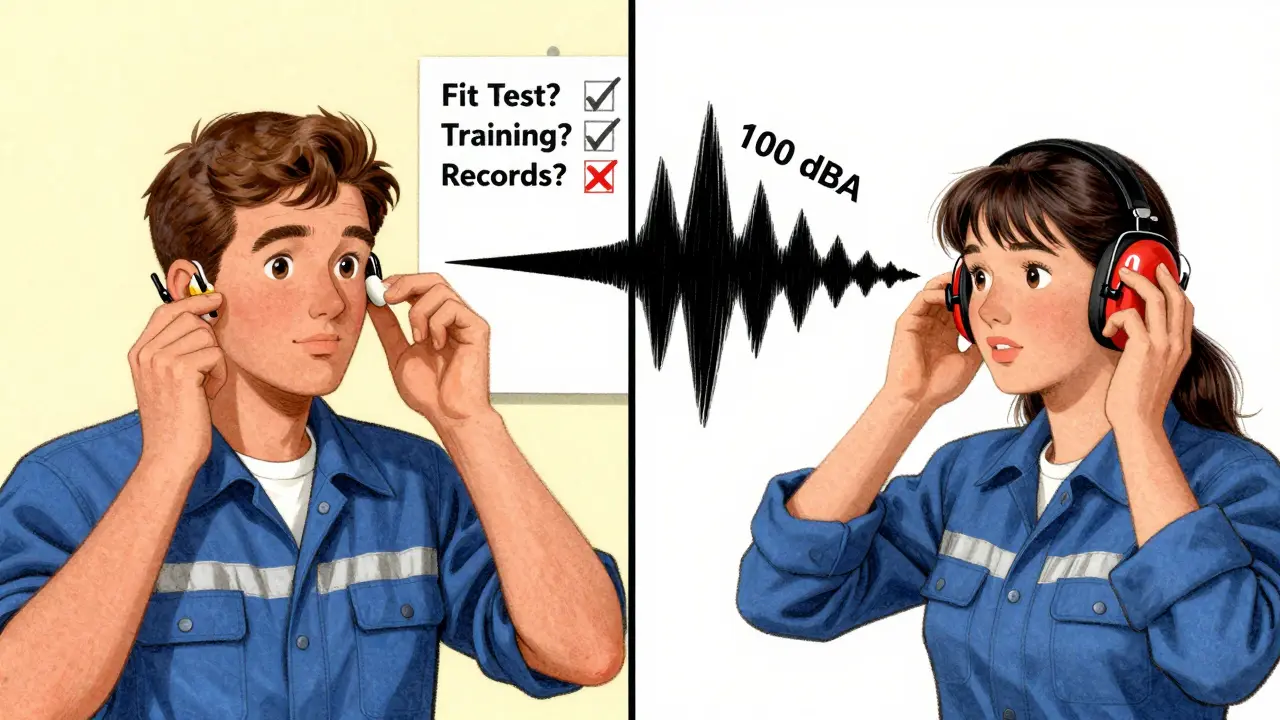

- Hearing protection: Employers must provide a variety of hearing protectors-earplugs, earmuffs, or both-and train workers on how to use them correctly. The goal isn’t just to hand out gear. It’s to make sure it actually works. Hearing protectors must reduce exposure to at least 90 dBA over an 8-hour shift.

- Training: Employees must get annual training that covers how noise damages hearing, how protectors work, why testing matters, and what to do if they notice hearing changes. Training can’t be a 10-minute slideshow. It needs to be interactive, repeated, and relevant to the job.

- Recordkeeping: All noise exposure records must be kept for at least two years. Audiometric test results must be stored for the entire time the employee works there. These records aren’t just paperwork-they’re legal proof you’re protecting your team.

How Audiometric Testing Works

Audiometric testing sounds simple: you put on headphones and press a button when you hear a tone. But behind that simple action is a strict protocol.

Before the test, the employee must be free from workplace noise for at least 14 hours. That means no loud concerts, power tools, or even loud music through headphones the night before. If they’ve been exposed to noise, the test results are invalid.

The test uses a calibrated audiometer that meets ANSI S3.6-2018 standards. Older machines using the outdated SC-1969 standard are no longer acceptable under proposed OSHA updates. The test checks hearing at five frequencies, with special attention to 2000, 3000, and 4000 Hz-where noise-induced hearing loss first shows up.

When a shift of 10 decibels or more is detected compared to the baseline, it’s called a Standard Threshold Shift (STS). This is a red flag. Within 21 days, the employer must notify the employee in writing. Within 30 days, they must: refit the hearing protector, retrain the worker, offer a higher-rated protector if needed, and refer them for a clinical evaluation if a medical issue is suspected.

One key detail: the baseline audiogram can be updated if the STS is confirmed as permanent. This prevents the same employee from being flagged year after year for the same loss. But it also means you can’t ignore early warning signs.

Why Most Programs Fail

OSHA issued over 1,800 citations for hearing conservation violations in 2022. The top two reasons? Inadequate testing (62%) and poor training (28%).

Here’s what actually goes wrong on the ground:

- Employees skip tests. A 2023 SHRM survey found that 68% of safety managers struggle with low participation. Workers think, “I can still hear fine,” or “I don’t have time.” But hearing loss doesn’t hurt. It sneaks up slowly. By the time someone notices, it’s too late.

- Protectors don’t fit. About half of all workers use hearing protection incorrectly. Foam earplugs rolled too tightly, earmuffs worn over long hair, or mismatched models that don’t seal properly can cut protection in half. Fit testing-where a device measures how well a protector works on a specific person-is rare in small businesses but critical.

- Records are messy or missing. Paper logs get lost. Digital systems aren’t updated. If OSHA shows up for an inspection and can’t find a test result from two years ago, the penalty can be $15,000 or more.

Small businesses are hit hardest. With fewer than 50 employees, 37% are non-compliant, compared to just 18% in larger companies. The cost of a full program-$250 to $400 per employee per year-feels steep. But the cost of ignoring it? Higher. Workers with hearing loss take more sick days, make more mistakes, and file more workers’ comp claims. One study found workplaces with good programs had 15-20% less absenteeism.

What’s Changing in 2025

OSHA’s proposed updates, expected to be finalized in late 2024, will raise the bar. By 2025, employers will need to:

- Use the latest ANSI S3.6-2018 audiometer calibration standard (not the old SC-1969).

- Test at 6000 Hz in addition to the current frequencies-this catches early high-frequency loss that’s often missed.

- Provide hearing protection rated for exposures above 100 dBA, not just 90 dBA. Many industrial environments now exceed 100 dBA, and current requirements are outdated.

These changes will raise program costs by 8-12%. But experts say they could prevent 150,000 new cases of hearing loss each year. The American Academy of Audiology points out that even 85 dBA over a 40-year career causes hearing loss in 8-12% of workers. That’s not a minor risk-it’s a public health issue.

How to Build a Program That Works

Don’t just meet the minimum. Build a program that people actually use.

- Use mobile testing units. Companies that bring audiometers on-site reduce employee downtime by 60%. No more scheduling trips to clinics. No more lost shifts.

- Train with real examples. Show workers their own audiograms (anonymized). Let them hear what a 10 dB shift sounds like. Make it personal.

- Offer choice. Some people hate earplugs. Others hate earmuffs. Give them options. Let them try three different types before picking one.

- Make it part of culture. Include hearing health in safety meetings. Reward teams with high participation. Celebrate zero STS years.

- Track and fix gaps. Use software to flag missed tests, outdated records, or protectors with low NRR ratings. Don’t wait for OSHA to find them.

One Vancouver manufacturing plant cut its STS rate by 70% in two years by switching to mobile testing and letting workers choose their own earplugs. They didn’t spend more-they spent smarter.

Who Needs This Program?

If your workplace has any of these, you’re likely covered:

- Factories with assembly lines or stamping presses

- Construction sites with jackhammers, saws, or pneumatic tools

- Airports and aviation maintenance shops

- Warehouses with forklifts and conveyor belts

- Fire stations with sirens and equipment noise

- Music venues or recording studios

- Farms with tractors, grain dryers, or chainsaws

Even if you have fewer than 10 employees, if noise levels hit 85 dBA, you’re still required to comply. There’s no small-business exemption under OSHA.

What Happens If You Don’t Comply?

OSHA fines for hearing conservation violations range from $15,625 to $156,259 per violation, depending on whether it’s classified as serious, willful, or repeat. A single missed annual audiogram can trigger a citation. A pattern of missed tests or untrained workers can lead to shutdowns.

But the real cost isn’t the fine. It’s the worker who can’t hear their child speak. The employee who loses their job because they can’t hear alarms. The family that deals with isolation, depression, and communication breakdowns because of preventable hearing loss.

Final Thoughts

Hearing loss is permanent. It doesn’t heal. It doesn’t get better with rest. Once it’s gone, no pill, no surgery, no hearing aid can fully restore it. That’s why a hearing conservation program isn’t just about rules-it’s about respect. Respect for your team’s health, their future, and their quality of life.

Start with the basics: test the noise, test the hearing, protect the ears, train the people, keep the records. Do it right, and you’re not just avoiding fines. You’re keeping people connected-to their work, their families, and the world around them.

Do all workplaces need a hearing conservation program?

No, only workplaces where employees are exposed to noise at or above an 8-hour time-weighted average of 85 decibels (dBA). This includes factories, construction sites, airports, warehouses, and other noisy environments. Even small businesses with fewer than 10 workers must comply if noise levels meet this threshold. Employers must measure noise exposure to determine if the program is required.

How often do employees need hearing tests?

Employees exposed to 85 dBA or higher must get a baseline audiogram within six months of starting the job. After that, annual audiometric tests are required. The test must be conducted in a quiet room, with the employee free from workplace noise for at least 14 hours before the test. Results are compared to the baseline to detect any hearing shift.

What is a Standard Threshold Shift (STS)?

An STS is a change in hearing sensitivity of 10 decibels or more, averaged across 2000, 3000, and 4000 Hz, compared to the employee’s baseline audiogram. If detected, the employer must notify the employee in writing within 21 days and take action within 30 days-such as retraining, refitting hearing protection, or referring the worker for a clinical evaluation. The baseline can be updated if the shift is confirmed as permanent.

What types of hearing protection are required?

Employers must provide a variety of hearing protectors, including earplugs and earmuffs, and ensure they reduce noise exposure to at least 90 dBA over an 8-hour shift. The protectors must be selected based on the noise level and fit properly. Fit testing is recommended but not yet required by OSHA. Workers should be trained on how to insert and wear them correctly for maximum effectiveness.

Can hearing loss from noise be reversed?

No. Noise-induced hearing loss is permanent and irreversible. Once the hair cells in the inner ear are damaged by loud noise, they do not regenerate. Hearing aids can help amplify sound, but they cannot restore lost hearing. That’s why prevention through hearing conservation programs is critical-there is no cure after the damage occurs.

What are the penalties for not having a hearing conservation program?

OSHA fines for violations range from $15,625 to $156,259 per violation, depending on severity and whether it’s classified as serious, willful, or repeat. Common violations include missed audiometric tests, lack of training, or failure to maintain records. In addition to fines, businesses may face shutdowns, lawsuits, or increased workers’ compensation claims due to preventable hearing loss.

Are there new OSHA rules coming for hearing conservation?

Yes. Proposed updates expected in late 2024 will require employers to use the latest ANSI S3.6-2018 audiometer calibration standard, test at 6000 Hz, and provide hearing protection rated for noise levels above 100 dBA-not just 90 dBA. These changes aim to catch early hearing loss and reflect current science. While they’ll increase program costs by 8-12%, experts say they could prevent 150,000 new cases of hearing loss each year.

Write a comment